IQC dep. will check the quality of raw materials, parts or products according to the GB2828 sampling standard. Qualified products will be stored to the raw material warehouse, and unqualified materials will be returned to the supplier.

Quality First

Excellent product quality is the core competitiveness of an enterprise’s long-term development. Winning by quality is the key for kontech to become the world’s leading supplier of intelligent customized display solutions.

In order to meet customers’ expectations for high quality and reliability, we continue to focus on process equipment upgrades, process optimization and employee professional skills training. Strict quality control system brings high-quality products. Kontech has accumulated a good reputation in the global market for 14 years, and is trusted by the majority of partners and consumers. We are proud of this.

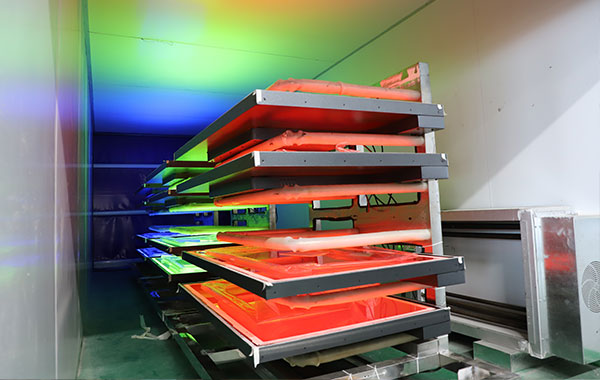

Quality Inspection System

Establishing a complete quality system is a necessary foundation for an industry-leading enterprise.

Kontech has the industry’s top quality testing laboratory, through which a number of internal tests are carried out on products. The testing standards conform to European and American international standards, so it can provide customers with products of ultra-high quality standards. In any link of the supply chain, Kontech’s product quality and reliability are reliable.